Pretty in pink

George Guidoni

Food Safety Metal Detection Software X-Ray BRC British Retail Consortium Chamber of Commerce Eagle MDX (Material Discrimination X-ray) Eagle Pack 430 Pro X-Ray Eagle Product Inspection Easy MAT HACCP (Hazard Analysis Critical Control Points) Jadee Meat Products Ltd. Plan AutomationFamily-owned Ontario meat processor leverages advanced X-Ray inspection technology to let its uncompromising focus on high product quality shine from plant to plate

Life is not always a bowl of cherries for companies making their living in today’s fiercely competitive Canadian red meat market. But for brothers Hershel and Micheal Snajdman, president and vice-president of Jadee Meat Products Ltd. in Beamsville, Ont., putting healthy high-quality meat products on the consumers’ plates is a labor of love, passion and pride that makes all the hard work along the way a joyful life-long endeavor.

Literally born into a family meat business started up by his grandfather Joseph and father Danny back in the 1950s in London, Ont., making his mark in the meat industry always seemed like a natural career path for Michael, who remembers helping his dad and grandpa out as a little boy at the company’s original processing plant in Hamilton, Ont.

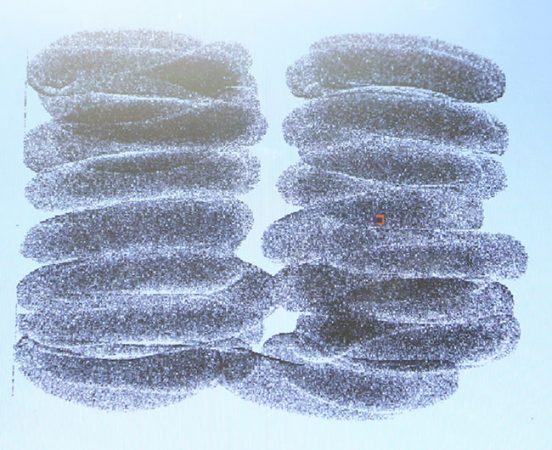

Thermoformed packages of diced ham pizza toppingspassing through the high-speed Eagle Pack 430 PRO model X-Ray inspection system to detect any bone fragments and other dense contaminants using advanced Eagle Material Discrimination X-ray (MDX) technology.

Ditto for Hershel, born shortly after his father and grandfather selected Beamsville as the strategic location for consolidating their existing old-school butcher shop operations in southern Ontario at one main federally-inspected meat processing facility to serve the entire Canadian market.

“When they first started building this facility in 1977, there was not a lot more than cherry and apple trees in the area, and while driving around looking for the perfect spot, my mom and dad heard an old ballad ‘Cherry Pink and Apple Blossom Time’ on the radio,” says Hershel Snajdman, relating the original inspiration for the name of company’s flagship Cherry Pink brand of processed deli meats, European-style hams

and sausage, bacon, and a wide range of meat toppings and ingredients sold by the company to the Canadian quick-service restaurant industry, leading food distributors, and select retail channels across Canada.

Explaining the company’s Jadee Meat Products moniker as a playful first-name tribute to founders Joseph and Danny (as in J.D.), Snajdman says the original 40,000-square-foot plant has enjoyed steady and consistent growth in sales and market share since it commenced operations in 1979.

Over the following years, the meat processing operation has undergone three significant facility expansions that more than doubled its processing square footage, while enabling it to evolve into a well-respected and reputable supplier of premium-quality products safely manufactured at a fully-accredited HACCP (Hazard Analysis Critical Control Points) plant that today also boasts the globally-recognized BRC food safety certification developed by the U.K.-based British Retail Consortium.

Running a steady two-shift operation on a five-days-a-week schedule, Jadee Meats has built its success on a solid foundation of innovation and time-honored European recipe authenticity and tradition to establish an exceptionally loyal client base and industry-wide respect for its Cherry Pink product brand family.

“Today we make toppings for most of the largest pizza chains operating in Canada,” Snajdman relates, “ranging from pepperoni and bacon to diced, sliced, julienne, quartered or shredded pork and beef toppings.

“We also do a lot of specialty custom work for larger food manufacturers by supplying them with the meat ingredients used in their frozen food products and other dishes, such as veal cordon bleu for example, as well as many other cooked and smoked meat products for deli operators and private-label customers.”

As Snajdman explains, the Beamsville plant operates multiple large-capacity smokehouses on-site—supported with world-class processing and packaging machinery assembled on the shop floor—to help provide many of its creations with the unrivalled taste and aroma that virtually let the Cherry Pink products sell themselves.

“The recipes we use today are very much the same recipes that the company started out with originally,” Snajdman says, “except we now do it with modern equipment and technologies.

“Our bacon is arguably of the most popular premium products we supply to the market,” Snajdman sates, citing the popular Ontario grocery retail chain Longo’s as one of its loyal retail customers stocking its shelve with Pink Cherry bacon and other processed meats.

“Most plants making bacon in Canada take about a day to produce the final product,” he points out, “whereas our bacon-making process takes well over a week.

“The result is a truly unique product that has a rich flavor, terrific texture, and very little shrinkage during the cooking process.

“We also do a lot of custom ham work, whereby we ship our hams to customers in bulk, have, sliced, quartered, diced, half-moon or whatever format the customer requires … there are so many things we can do with one primary product,” Snajdman extols.

“It’s a customer-driven business,” he states, “and we take pride in giving our customers exactly what they want.”

Snajdman explains that about 60 per cent of the plant’s output is derived from pork meat and the rest from beef, with all of the large primary cuts of meat shipped to the Beamsville plant already de-boned and defatted at the suppliers’ slaughterhouses—allowing the Jadee plant to focus on its core “further processing” operations.

Says Snajdman: “We are helping our customers to improve their business by supplying them with custom solution that some of the larger meat processors may not want to do, for various reasons.

“We are pleased with our client mix of branded products, the co-packing work we do for our meat market customers, and the many QSR (quick-service restaurant) operators that we supply,” Snajdman states.

In addition to keeping the plant’s production machinery constantly updated to keep up with the times, Snajdman says he takes a lot of pride in the family-like work culture fostered at the Beamsville plant, which is one of the larger industrial employers in the Niagara region.

“We always stress to our staff the importance of treating others like they would want to be treated themselves,” he says, “and hopefully that extends right up to the management level.

“Our average tenure among staff at this plant is over 20 years,” he points out.

“People who join us tend to stay with us, and we’re very grateful for that—they are great people.”

Having been part of the local community’s business landscape for such a long time has also enabled Jadee Meat to build and cultivate a highly favorable public image among the locals, according to Snajdman, who cites several local Chamber of Commerce awards given to the plant over the years for its various proactive community and business initiatives that include generous donations to local food banks and other like-minded community causes.

“Our storefront at the building’s entrance is a good example of this community bridge-building,” Snajdman states.

“It is only open for business three days a week, but you’d be surprised how many people come through here in those three days,” he remarks. “Some of the customers will even drive from a long way out to buy up to two cases of meat at a time that they can take up north with them to the cottage or camping.”

Jadee Meat Products plant employee Cody Mabon conducting a thorough quality check on the rows of high-quality meat sausages produced at the company’s state-of-the-art production facility in strict accordance to authentic European recipes and cooking methods.

Says Snajdman: “It’s a very nice and tight community here, and we’re happy to serve it by being able to offer people really high-quality meat products at very affordable prices.

“People here really appreciate it,” he says. “It is actually a very small part of our business, but if we were to shut it down, a lot of people around here would be upset with us.”

With premium product quality being one of the meat processor’s biggest calling cards and competitive advantages, the plant leaves nothing to chance to allow its stellar industry reputation be tarnished through any accidental quality defects or product recalls.

While the operation has long enjoyed a virtually spotless product safety record, Snajdman is a firm believer that there is no such thing as too much safety when it comes to food.

This mindset played a large part in the company’s recent decision to invest in additional advanced X-Ray inspection technology to complement its existing X-Ray system and a series of high-quality metal detectors installed throughout the plant at all the usual critical points to ensure uncontaminated finished products.

“We wanted to go with X-Ray technology because there are some products that are more likely to contain bone fragments within them,” Snajdman explains.

“Just the thought of someone out there chipping their tooth because they bit into a bit of bone in our meat product is unacceptable to us,” he states.

“We felt that investing into a technology to prevent that kind of thing from happening is well worth the expense,” he states.

“We want people to enjoy eating our products, not to get hurt doing it,” says Snajdman, “and X-Ray inspection is a wonderful technology for detecting bone particles within the meat.

“In addition to bone detection, the X-Ray technology also allows us to detect metal particles much smaller than most conventional metal detectors can do,” Snajdman notes, “and we really enjoy that additional peace-of-mind it offers.”

As Snajdman relates, all finished packaged products processed at the plant that are prone to harboring bone fragments pass through one of the plant’s X-Ray inspection units at the end of the line prior to being cased and shipped out.

To help Snajdman obtain his peace-of-mind, the plant’s long-time technology partners PLAN Automation, Orangeville, Ont.-based supplier of packaging automation products and line integration services, proposed the installation of a highly advanced Eagle Pack 430 PRO X-Ray inspection system manufactured by Eagle Product Inspection in Tampa Bay, Fla.

After assessing other options, Snajdman said he became quickly convinced about the Eagle Pack 430 Pro model being a perfect fit for his plant’s needs.

“We just felt that the Eagle unit was more robust compared to the other X-Ray systems in the market,” he states.

“Combined with our long and productive relationship with PLAN Automation, who also supplied us with many of our metal detectors over the years, we felt very confident about obtaining an optimal food safety solution for our premium products.”

Installed about a year-and-a-half ago, the Eagle Pack 430 PRO X-Ray inspection system has lived up to all its promises, according to Snajdman, who credits Plan Automation’s vice-president and chief operating officer Mat Bédard for overseeing a smooth and flawless system installation at the plant, while also providing all the necessary training and technical support.

According to Bédard, the key to the Eagle Pack 430 PRO’s exceptional performance lies in the system’s proprietary Eagle MDX (Material Discrimination X-ray) technology designed to enable highly accurate detection of lower-density contaminants such as bone, glass shards, rubber, plastic, etc., by discriminating inspected materials by atomic number (chemical composition) to process “busy” images with high variation in image density.

Originally developed for use in the security sector, the innovative Eagle MDX is now widely available for food and beverage producers to trace and pinpoint traditionally undetectable contaminants such as bone fragments, plastics bits and glass shards.

The proprietary Eagle Material Discrimination X-ray (MDX) technology incorporated into the Eagle Pack 430 is a powerful inspection tool that can actually pinpoint the location of an unwanted particle of bone or other contaminants in the product with a red dot appearing on the X-Ray image.

Moreover, the Eagle MDX technology uses Easy MAT software that facilitates faster installation and simplified set-up by auto-learning the material composition of the product, according to Eagle.

Unlike many food companies who have been mandated by their customers to install X-Ray inspection at their packaging lines as part of larger food supply chain safety initiatives, “Investing in this Eagle unit was simply a case of us being proactive,” according to Snajdman.

“We were already meeting and exceeding out customers’ expectations for quality and safety with our current practices,” he points out, “so it wasn’t a case of us having a problem that we needed to fix.

“We were guided purely by our desire to ensure that there is no bone getting shipped out with our product to the customers,” says Snajdman, praising the Eagle system’s operational flexibility that allows it to perform high-speed inspection of a diverse range of packages—from 500-gram thermoformed packs to 2.5-kilogram vacuum-packed whole hams and other large cuts.

“It works just as well on fully-sealed products as it does on loose packs, depending on the products,” Snajdman says.

“We do a lot of MAP (modified-atmosphere packaging) work, vacuum-sealed barrier packaging, skin-packs and all the other common meat packaging formats,” says Snajdman, adding the company PLAN Automation Eagle Product Inspection only purchases high-quality packaging from reputable suppliers to produce final packaging on its state-of-the-art meat packaging machinery.

While Snajdman says he thoroughly enjoys being in the meat business, “It is definitely an industry that has a fair share of challenges.

Says Snajdman: “I love our product, I love the idea of providing fresh and local products to the market, and I love the idea of being a Canadian meat producer.

“But food safety continues to be a huge challenge,” he states, “and the industry as a whole is very competitive.

Since beginning operations in 1979, the Jadee Meat Products meat processing plant in Beamsville has undergone three major expansions that have doubled to size of the original building to over 80,000 square feet, while keeping the operation up to date with the latest modern meat processing and packaging technologies to grow market share across Canada.

“The industry has shrunk significantly in the last few years, with many medium-sized operations like ourselves being consolidated into fewer but much bigger meat-packing operations.

“There are not that many mid-sized meat processors like us left in Canada nowadays,” he reflects, “but we have many reasons to feel positive about the future going forward.

“A lot of Canadians are eating our products on a weekly basis, often without realizing where these products came from, but that is perfectly alright with us,” he says.

“A lot of our large QSR customers have been with us for over 25-plus years,” he states, “ and that would not be the case if we did not provide them with the right competitive solutions for their business that solve their specific problems and challenges.

“We’re not trying to be everything to everybody,” Snajdman concludes, “but having established ourselves as a reliable supplier of custom solutions for our customers’ many different needs, we are confident about being able to rise to whatever challenges the market throws our way.”

Advertisement